- Home

- About Us

- Products

- MACHINE

- WELDING ACCESSORIES

- WELDING CONSUMABLES

- WELDING FLUX

- GAS EQUIPMENTS

- SAFETY PRODUCTS

- ABRASIVES

- TOOLS

- Download

- News

- Contact Us

Web Menu

- Home

- About Us

- Products

- MACHINE

- WELDING ACCESSORIES

- WELDING CONSUMABLES

- WELDING FLUX

- GAS EQUIPMENTS

- SAFETY PRODUCTS

- ABRASIVES

- TOOLS

- Download

- News

- Contact Us

Product Search

Exit Menu

Products

Products

- MACHINE

- WELDING ACCESSORIES

- WELDING CONSUMABLES

- WELDING FLUX

- GAS EQUIPMENTS

- SAFETY PRODUCTS

- ABRASIVES

- TOOLS

- WELDING TOOLS

- MAGNETIC SQUARE

- INSPECTION MIRROR

- ROD CANNISTER

- CORNER CLAMP

- CYLINDER KEY

- SPARK LIGHTER / FLINT

- TIP CLEANER

- SOAPSTONE HOLDER / SOAPSTONE

- WELDING GAUGE

- MIG PLIERS / MIG NOZZLE REAMER

- CHIPPING HAMMER

- F-CLAMP

- LOCKING PLIERS

- WELDING MACHINE TROLLEY

- INFRA RED DIGITAL THERMOMETER

- CYLINDER RACK

- GAS TESTER

- ELECTRODE OVEN

- HAND TOOLS

- POWER TOOLS

- PNEUMATIC TOOLS

- WELDING TOOLS

CONTACT

- Tel : +86-575-87012323

- Fax : +86-575-87266559

- Email : export@lissam.com

- Address :

Fl. 4th, #5 Qingchuan Building No. 10 Huancheng Road (N) Zhuji, Zhejiang

China 311800

Feedback

Details

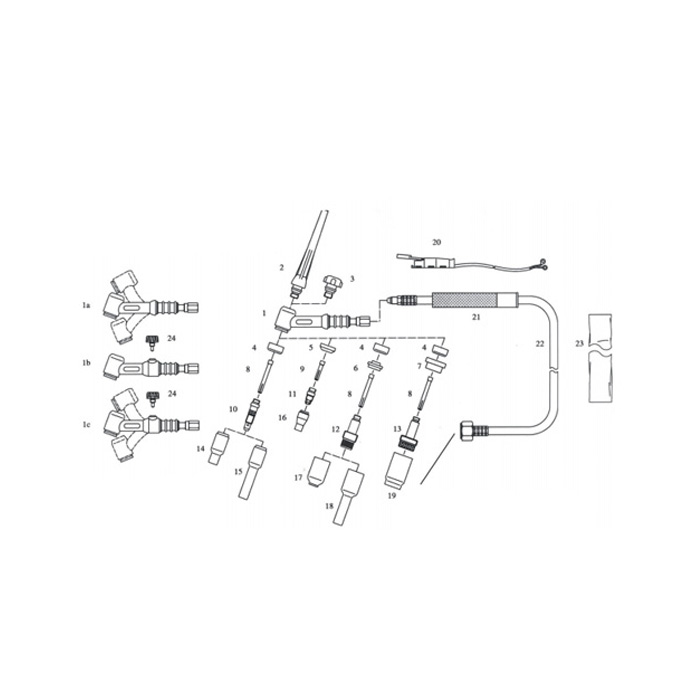

| No. | Description | Part No. |

| WP-17 Torch(Gas and Cable Whole) | WP-17-1(4M) | |

| WP-17 Torch(Gas and Cable Whole) | WP-17-1(8M) | |

| WP-17 Torch(Gas and Cable Separate) | WP-17-2(4M) | |

| WP-17 Torch(Gas and Cable Separate) | WP-17-2(8M) | |

| 1 | Torch Body | WP-17 |

| 1a | Torch Body(Flexible) | WP-17F |

| 1b | Torch Body(Valve) | WP-17V |

| 1c | Torch Body(Flexible and Valve) | WP-17FV |

| 2 | Long Back Cap | 57Y02 |

| 3 | Short Back Cap | 57Y04 |

| 4 | Gasket | 18CG |

| 5 | Stubby Gasket | 18CG-20 |

| 6 | Gas Lens Insulator | 54N01 |

| 7 | Large Dia. Gas Lens Insulator | 54N63 |

| 8 | Collet | 10N21.0.5mm |

| 10N22.1.0mm | ||

| 10N23.1.6mm | ||

| 10N23M.2.0mm | ||

| 10N24.2.4mm | ||

| 9 | Stubby Collet | 10N21S.0.5mm |

| 10N22S. 1.0mm | ||

| 10N23S,1.6mm | ||

| 10NS,2.0mm | ||

| 10N24S.2.4mm | ||

| 10 | Collet Body | 10N29.0.5mm |

| 10N30.1.0mm | ||

| 10N31,1.6mm | ||

| 10N32.2.4mm | ||

| 11 | Stubby Collet Body | 17CB20,All size |

| 12 | Medium Gas Lens | 45V29.0.5mm |

| 45V24.1.0mm | ||

| 45V25,1.6mm | ||

| 45V26.2.4mm | ||

| 13 | Large Long Gas Lens | 45V116,1.6mm |

| 45V64.2.4mm | ||

| 14 | Ceramic Nozzle | 10N50.6mm |

| 10N49,8mm | ||

| 10N48.10mm | ||

| 10N47.11mm | ||

| 10N46.13mm | ||

| 10N45.16mm | ||

| 10N44.19mm | ||

| 15 | Extra Length Ceramic Nozzle | 10N49L,8mm |

| 10N48L.10mm | ||

| 10N47L,11mm | ||

| 16 | Stubby Ceramic Nozzle | 13N08.6mm |

| 13N09.8mm | ||

| 13N10,10mm | ||

| 13N11,11mm | ||

| 13N12.13mm | ||

| 13N13.16mm | ||

| 17 | Ceramic Nozzle | 54N18.6mm |

| 54N17,8mm | ||

| 54N16.10mm | ||

| 54N15.11mm | ||

| 54N14.13mm | ||

| 54N19.19mm | ||

| 18 | Extra Long Ceramic Nozzle | 54N17L,8mm |

| 54N16L.10mm | ||

| 54N15L.11mm | ||

| 19 | Extra Dia. Ceramic Nozzle | 57N75,10mm |

| 57N74.13mm | ||

| 53N88.16mm | ||

| 53N87.19mm | ||

| 20 | Switch(with wire) | |

| 21 | Handle | 105Z55 |

| 22 | Cable Assembly | |

| 23 | Cable Assembly Cover | |

| 24 | Valve Stem | VS-2 |

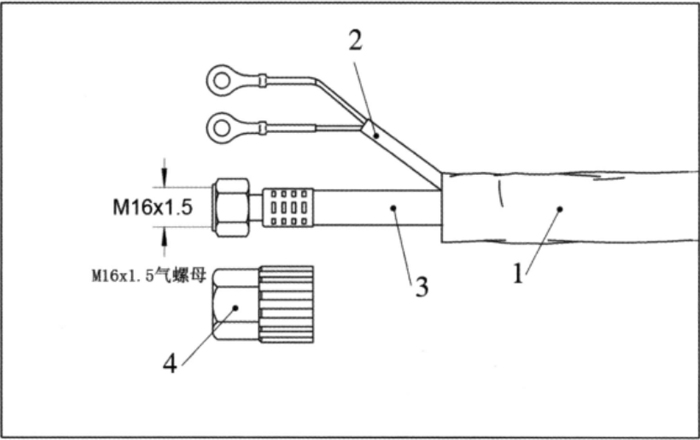

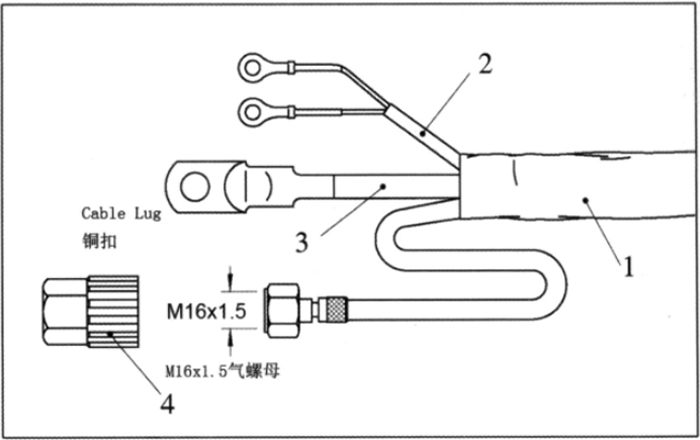

WP-17,WP-17F,WP-17V,WP-17FV Torch Terminations (Cable Gas Whole)

| NO. | Description |

| 1 | Cable Assembly Cover, For 4M(12.5 feet), Rubber/Jean |

| Cable Assembly Cover, For 8M(25 feet), Rubber/Jean | |

| 2 | Control Wire |

| 3 | Cable 10mm²,4M(12.5 feet) |

| Cable 10mm²,8M(25 feet) | |

| 4 | Nut Cup(SW19) |

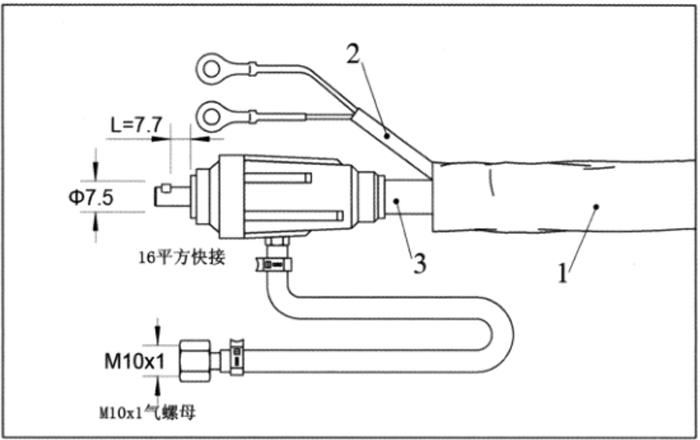

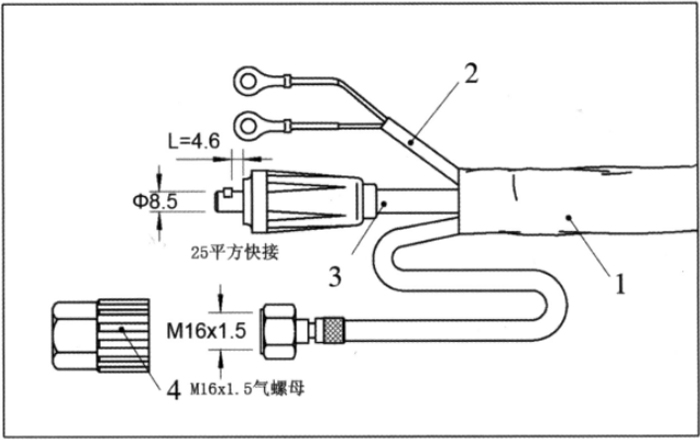

| NO. | Description |

| 1 | Cable Assembly Cover, For 4M(12.5 feet), Rubber/Jean |

| Cable Assembly Cover, For 8M(25 feet), Rubber/Jean | |

| 2 | Control Wire |

| 3 | Cable 10mm²,4M(12.5 feet) |

| Cable 10mm²,8M(25 feet) |

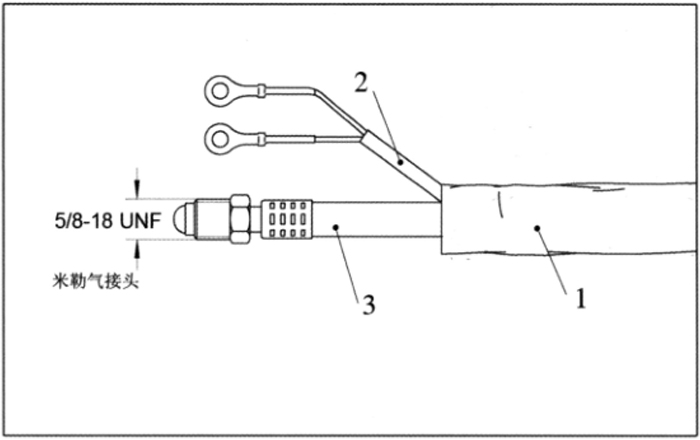

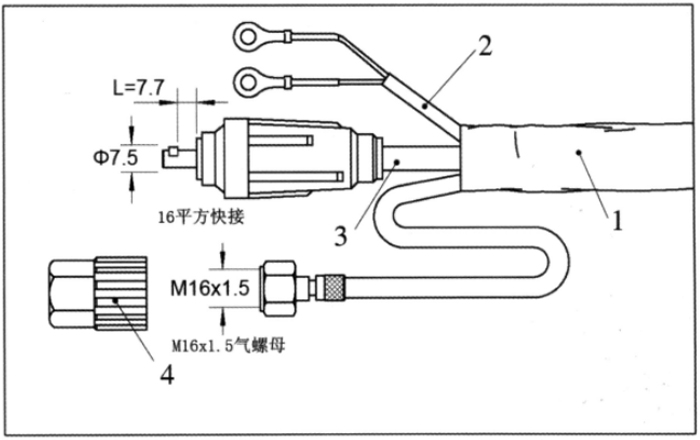

| NO. | Description |

| 1 | Cable Assembly Cover, For 4M(12.5 feet), Rubber/Jean |

| Cable Assembly Cover, For 8M(25 feet), Rubber/Jean | |

| 2 | Control Wire |

| 3 | Cable 10mm²,4M(12.5 feet) |

| Cable 10mm²,8M(25 feet) |

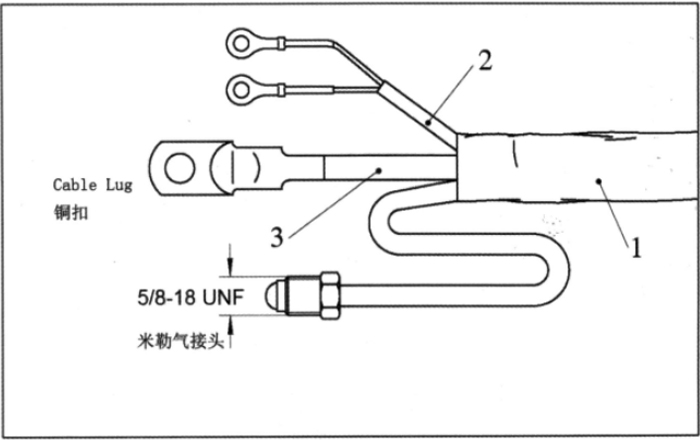

WP-17,WP-17F,WP-17V,WP-17FV Torch Terminations(Cable Gas Whole)

| NO. | Description |

| 1 | Cable Assembly Cover, For 4M(12.5 feet), Rubber/Jean |

| Cable Assembly Cover, For 8M(25 feet), Rubber/Jean | |

| 2 | Control Wire |

| 3 | Cable 10mm²,4M(12.5 feet) |

| Cable 10mm²,8M(25 feet) | |

| 4 | Nut Cup(SW19) |

| NO. | Description |

| 1 | Cable Assembly Cover, For 4M(12.5 feet), Rubber/Jean |

| Cable Assembly Cover, For 8M(25 feet), Rubber/Jean | |

| 2 | Control Wire |

| 3 | Cable 16mm²,4M(12.5 feet) |

| Cable 16mm²,8M(25 feet) | |

| 4 | Nut Cup(SW19) |

| NO. | Description |

| 1 | Cable Assembly Cover, For 4M(12.5 feet), Rubber/Jean |

| Cable Assembly Cover, For 8M(25 feet), Rubber/Jean | |

| 2 | Control Wire |

| 3 | Cable 16mm²,4M(12.5 feet) |

| Cable 16mm²,8M(25 feet) | |

| 4 | Nut Cup(SW19) |

| NO. | Description |

| 1 | Cable Assembly Cover, For 4M(12.5 feet), Rubber/Jean |

| Cable Assembly Cover, For 8M(25 feet), Rubber/Jean | |

| 2 | Control Wire |

| 3 | Cable 16mm²,4M(12.5 feet) |

| Cable 16mm²,8M(25 feet) |

-

- feedback

-

-

- Quick Links

- About us

- Products

- News

- Contact us

English

English 淘宝商城

淘宝商城